End-of-Line(EOL) Inspection

Ensuring quality in the final production stage of drones is key to preventing accidents and securing reliability.

Optimization of manufacturing line integration

Integratable as a fixed inspection device without modifying existing process lines

Non-contact comprehensive aircraft inspection

Comprehensive non-contact inspection of drone assembly quality, external condition, and integrity of key components using analog and vision sensors for multi-faceted examination

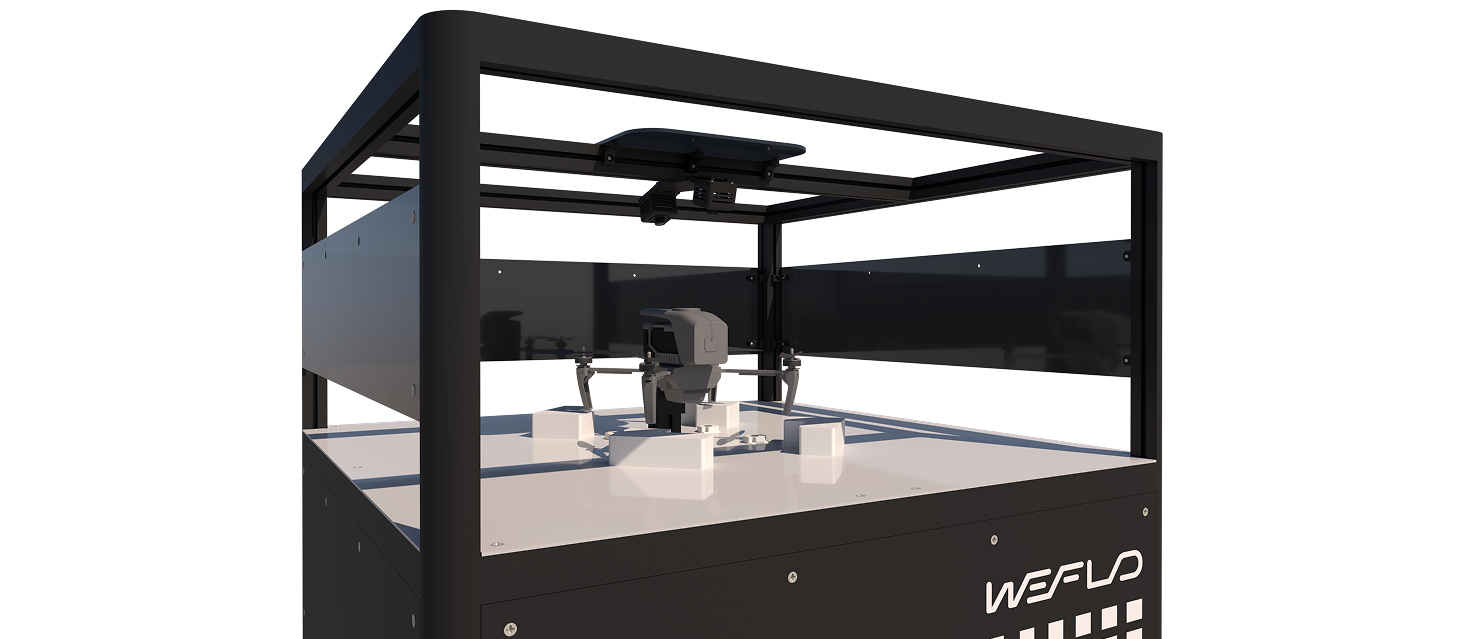

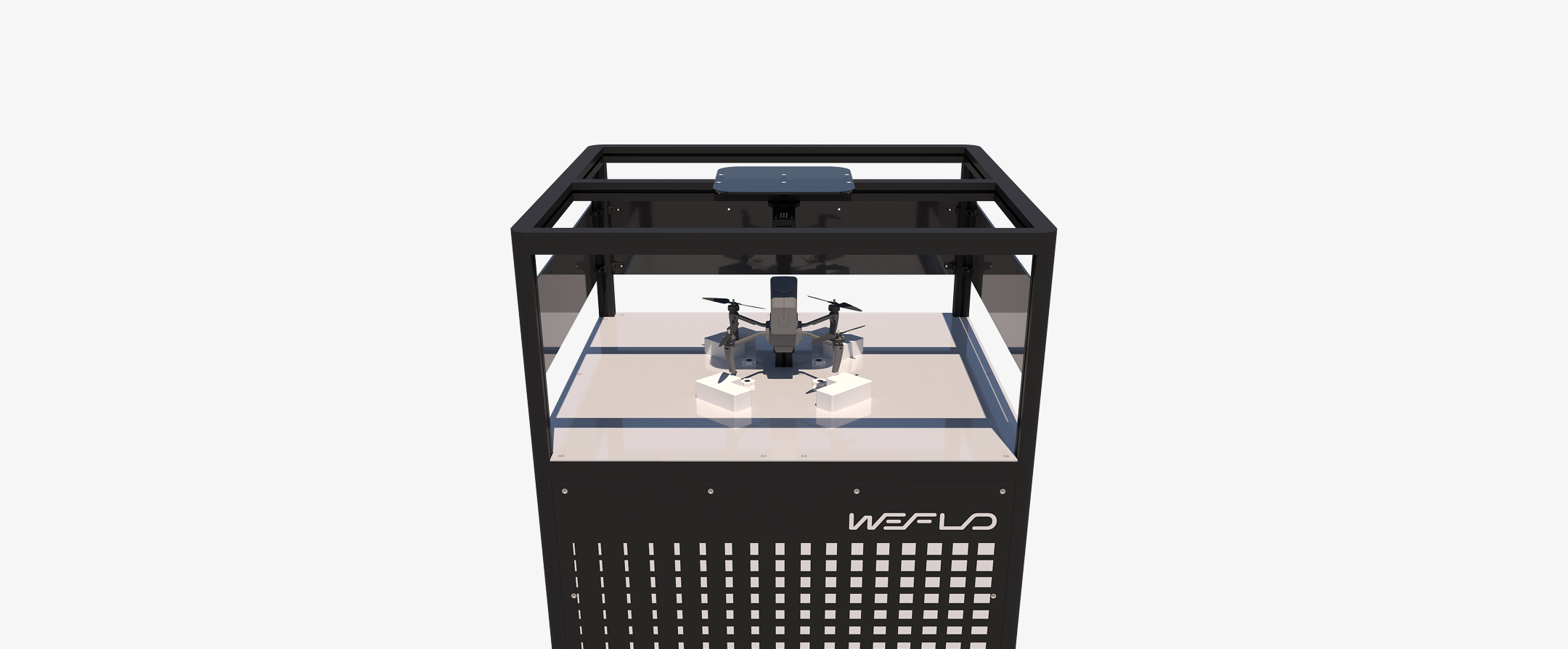

Integrated sealed structure

Independent, box-type structure protecting the inspection process from external environments and enhancing precision

AI algorithm-based automatic detection of assembly errors and defects

Analyze data and diagnose abnormalities through AI algorithms

Establishment of a data-driven quality management system

Proactive quality management and process optimization through understanding quality levels and predicting potential issues based on inspection data

Defect pattern recognition and warning system

Alerts managers to recurring errors in specific components or assembly processes

Generating quality report

Generates quality diagnostic reports for each aircraft to support rapid decision-making

How to use

Attach the drone to the fixed bar

Mounting or drone stabilization after assemblym

Automatically acquire data

Acquire data through onboard sensors during arming status

Analysis AI data

Determine abnormalities through fault diagnosis algorithms

Save inspection results and transmit history

Automatically save inspection results and upload to central operating system when needed

Customer value

Stabilization of shipping quality through quantified inspection

- Inspection of up to 15 items (e.g., rotation speed, balancing, damage)

- Automatic detection of assembly defects before shipment → Prevention of field issues and after-sales service

90% reduction in quality analysis time, improved productivity

- Manual QC 10 minutes → Automated inspection 1 minute

- Increased analysis speed + improved on-site responsiveness → Reduced risk of delivery delays

Data-driven quality standardization and history management

- Automatic recording of inspection results and AI labeling → Ensures traceability

- Application of customer-specific inspection standards → Minimization of manufacturing process simplification

Use case

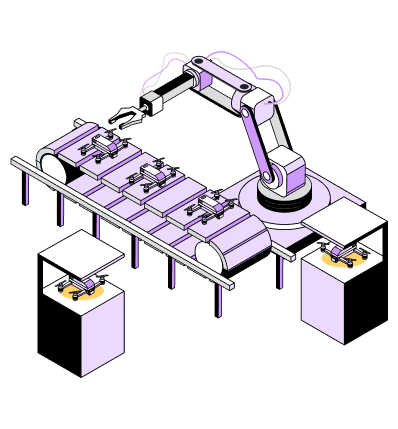

Drone Manufacturers

Final quality inspection of assembled aircraft

Drone production line for defense delivery

Automation of safety verification and shipping standards

UAV OEM and ODM manufacturing environment

Automation of repetitive inspections and quality tracking

SPEC

Size

1000x1000x1300 (mm)

Custom configuration available by aircraft specifications and type

Min 1.8m ~ Max 15m

| Inspection Items | |

|---|---|

Item 1 | Motor RPM |

Item 2 | Motor coilopen/short |

Item 3 | Blade installation direction |

Item 4 | Blade balance |

Item 5 | Arm structural fatigue |

Item 6 | ESC operation frequency |

Item 7 | Drive unit response time |

Item 8 | Drive unit balance |

Item 9 | Aircraft vibration frequency |

Item 10 | Exterior (crack, scratch, structure, etc.) |

Item 11 | Thermal status |

Item 12 | Battery charge status |

Item 13 | Magnetic sensor auto calibration |

Item 14 | FCC electronic status |

Item 15 | Onboard sensors status |

To be customized by customers' needs