Automated Aircraft Exterior Inspection

Aircraft exterior inspection is the starting point for safe operation and responsible maintenance.

Non-contact exterior defect detection

Precisely scan exterior condition without physical contact with the aircraft using high-resolution cameras and sensors

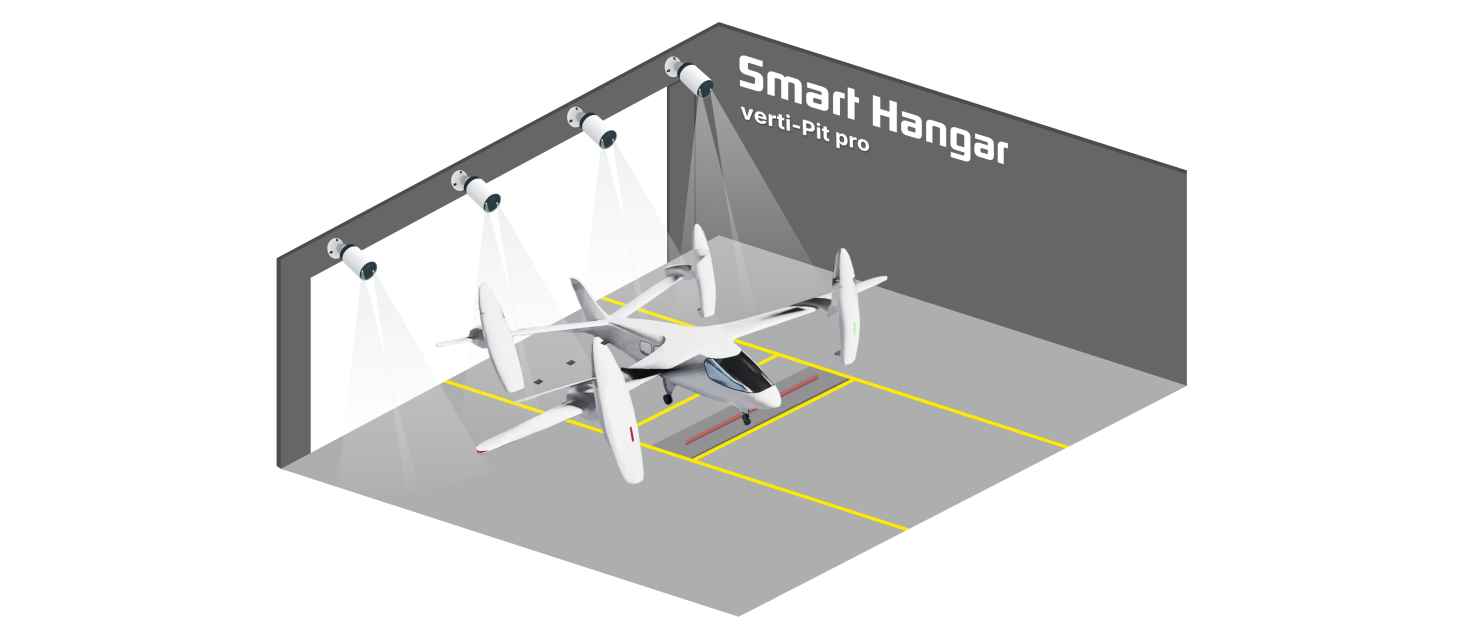

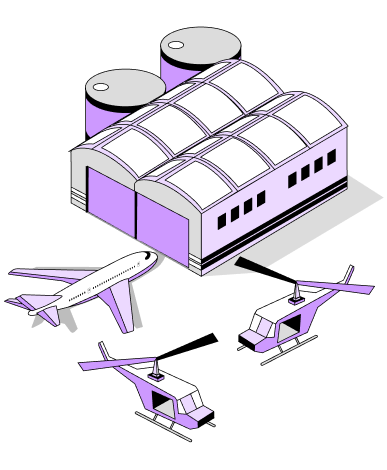

Gate/Hangar-type structure

Video sensors installed in a gate or hangar configuration to inspect the exterior as the aircraft passes through

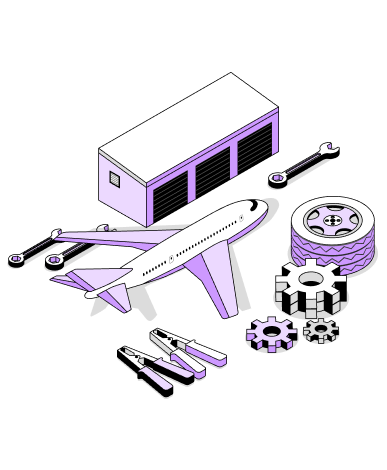

Automated scan and data acquisition

Automatically scan the entire exterior and acquire image data as the aircraft passes through, providing basic data for AI-based defect analysis

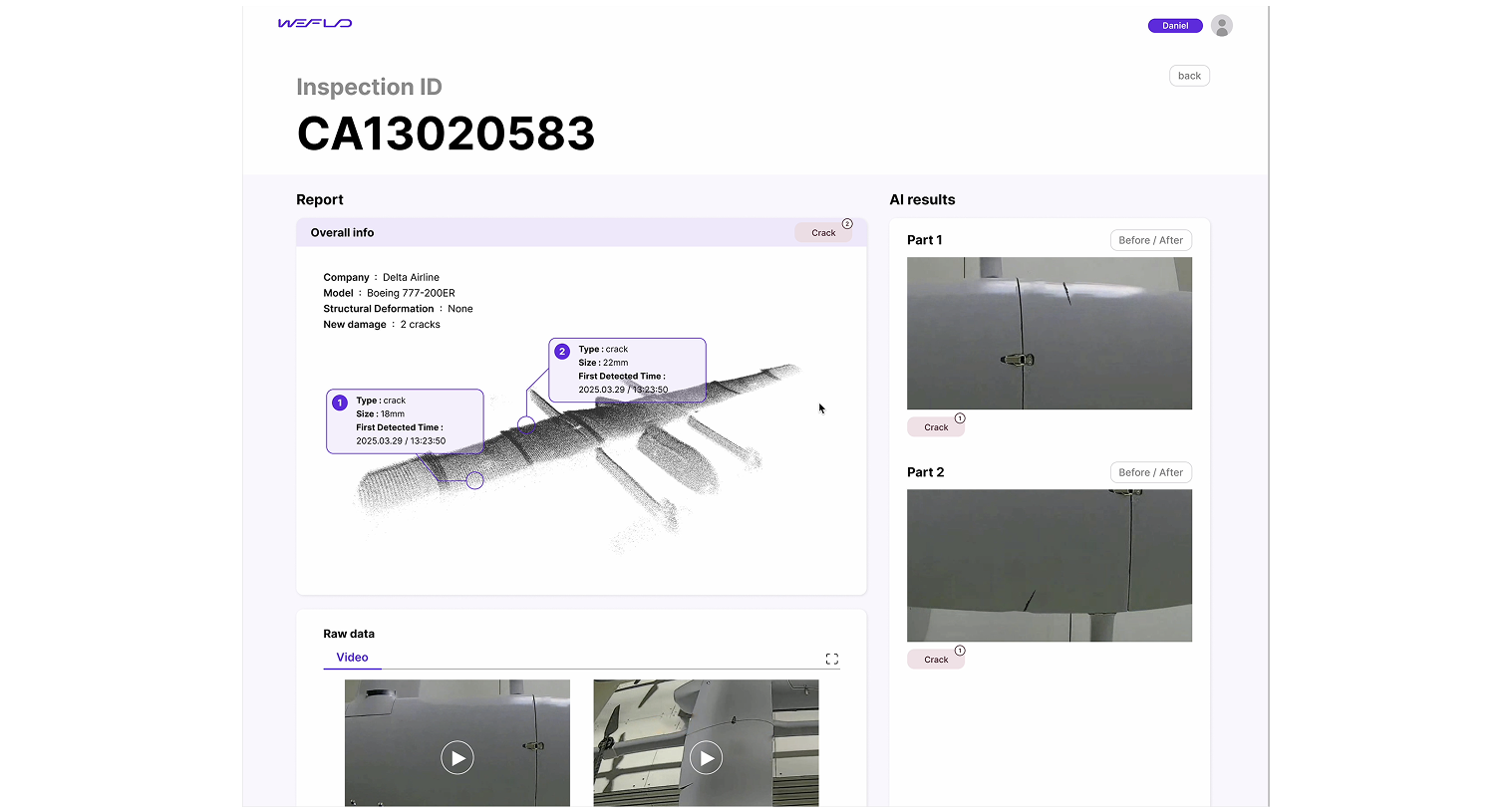

Aircraft history management dashboard

Visualizes defect trends, maintenance history, and operating hours for each aircraft to support aircraft health and lifespan prediction

AI-analysis-based automatic defect judgment

AI deep learning algorithm analyzes exterior image data to automatically judge defects

Ensuring inspection results and traceability

Provides clear evidentiary data for root cause analysis and accountability by tracing data at the time of inspection

Visualization of before/after service status

Visually presents an intuitive image comparison of the aircraft's exterior condition before and after maintenance or specific service performance

How to use

Aircraft landing and positioning

Aircraft passing designated inspection location (gate, hangar, etc.)

Automated exterior scan

Acquire data by scanning key areas of the aircraft from multiple angles using onboard vision sensors

AI Analysis

Determine defects by AI analysis of collected images

Generate defect report

Automatically save inspection results and generate reports

Customer value

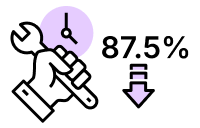

Up to 87.5% reduction in arrival/departure inspection time

- Exterior inspection time: 4 hours per aircraft → 0.5 hours

- Annual savings of approximately 17,500 hours + significantly improved efficiency of maintenance personnel resources

Clearer accountability through objective exterior inspection

- Quantitative recording of defects such as damage, separation, cracks, etc., through automated scan after landing

- Distinction between damage occurring during maintenance vs. during operation → Minimization of claim disputes

Improved maintenance quality through before and after service comparison

- Provision of visualized reports based on arrival/departure data

- Ensures maintenance quality history + enables analysis of recurring anomaly patterns

Use case

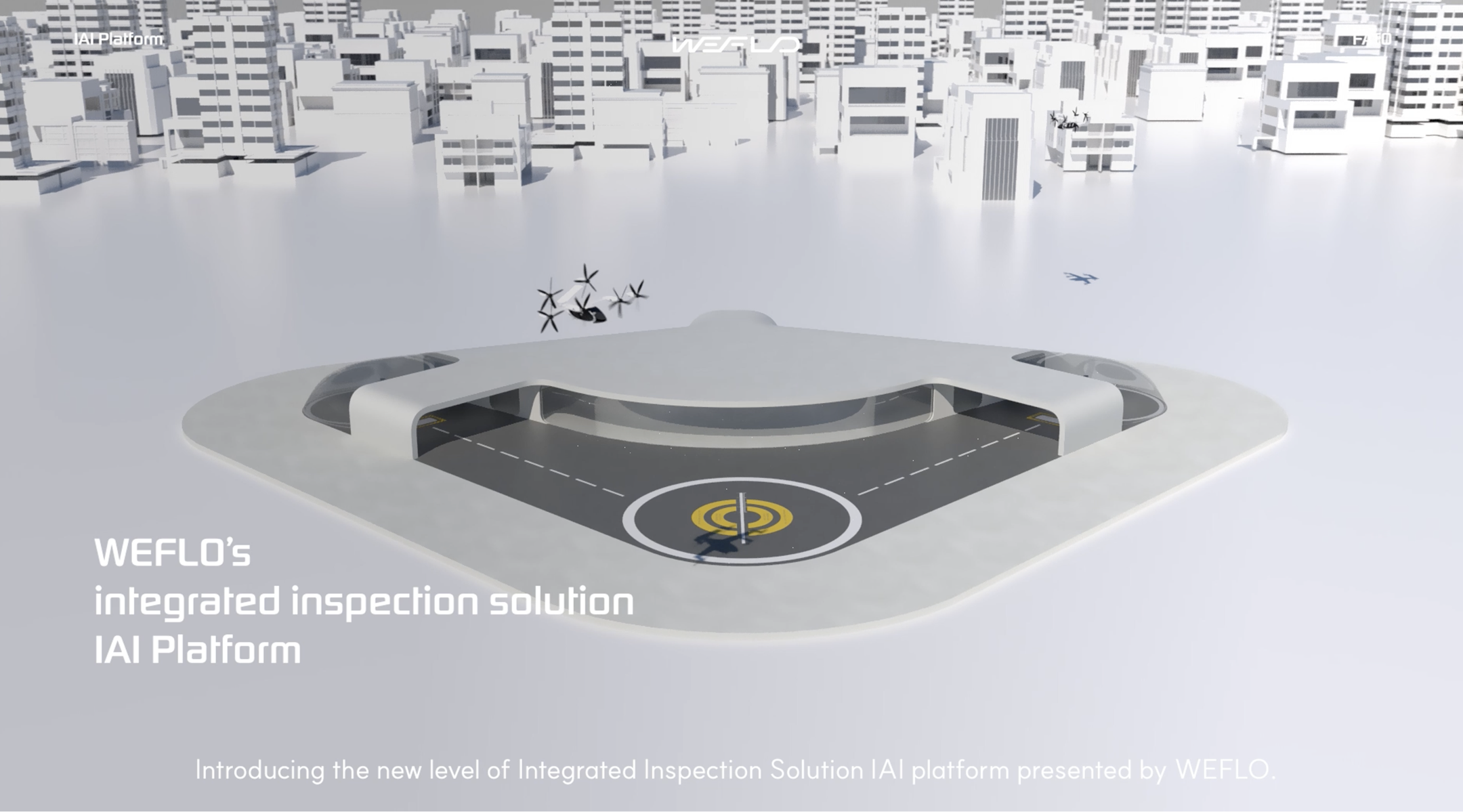

AAM/UAM Operators

Automated exterior inspection immediately after landing

Vertiports and Maintenance Facilities

Record of before and after maintenance status comparison

Heliport-based Air Transport Operators

Automated inspection process

for aircraft arrival and departure

Aircraft Sharing

Automatic recording of damage timestamp