Portable Smart Landing Pad

A portable drone diagnostic solution for fast and accurate diagnosis on-site.

Non-contact aircraft defect diagnosis

Acquisition of key component data such as motor, blade, control unit, and body within seconds without disassembling or connecting the drone

Enhanced durability and environmental adaptability

Robust structure designed for stable operation even in harsh outdoor environments

Compact portable type

Lightweight design for easy portability, usable by moving to any site

Easy and quick installation/dismantling

Can be installed and dismantled immediately on-site with minimal time and personnel

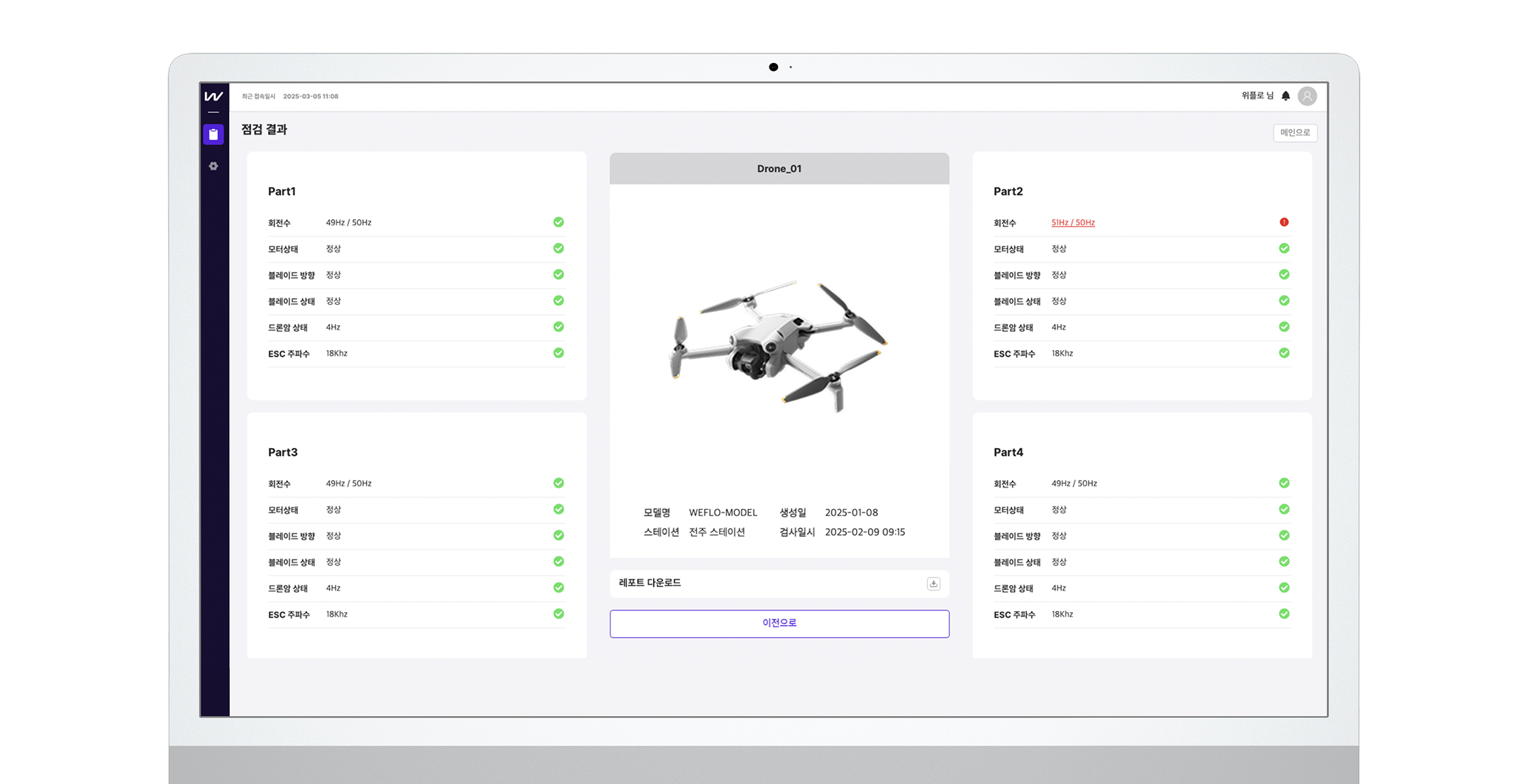

Real-time fault diagnosis

Analysis of inspection data obtained through sensors and fault diagnosis

Aircraft aging diagnosis

Predicting maintenance timing by analyzing part wear and aging based on inspection history

Easy storage of inspection results and report generation

Generating reports by storing completed inspection data and analyzing data

Support for rapid decision-making and on-site action

Fast action through diagnostic guidance on fault causes

How to use

Fix drone position

Position the drone accurately on the pad before takeoff and after landing

Automatic data acquisition

Acquire data through onboard sensors during arming status

AI data analysis

Determine abnormalities through fault diagnosis algorithms

Transmission of inspection results

Automatically save inspection results and upload to central operating system when needed

Customer value

Accident prevention by ensuring safety before takeoff

- Automatic inspection of 9 items including motor rotation speed, direction, and balancing

- Pre-emptive blocking of potential risks before takeoff → Reduction in accident rate

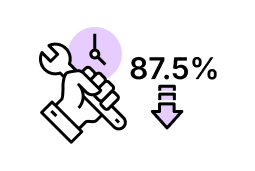

87.5% reduction in inspection time

- Manual 8 minutes → Automated 1 minute

- Same quality inspection without skilled personnel → Reduced labor burden

Maximizing on-site responsiveness with a portable structure

- No external power or fixed infrastructure required

- Immediately usable anywhere, including temporary airfields, disaster areas, and forests

Use case

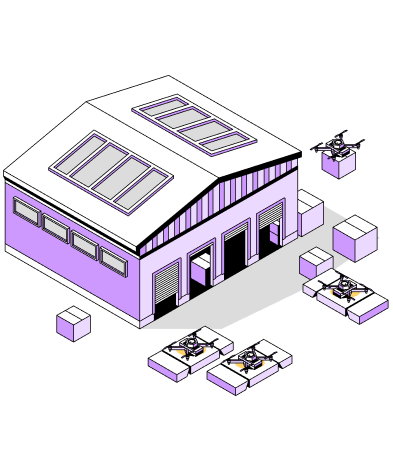

Drone Delivery and Logistics Operation Sites

Pre-inspection of delivery drones, logistics drones, etc.

Isolated Terrain Missions such as Forestry, Disaster Relief, and Surveying

Immediate on-site judgment and action regarding abnormalities

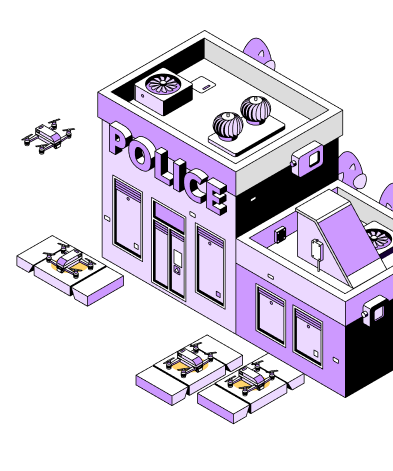

Military, Police, and Security Drone Operation Environments

Proactive prevention of potential defects during mission execution

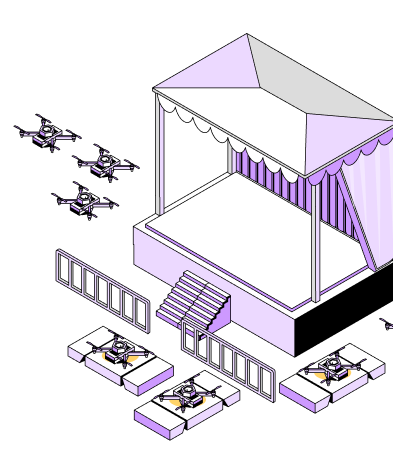

Outdoor Temporary Airfields and Event Drone Operations

Ensuring operational flexibility on-site and minimizing the risk of safety accidents

SPEC

Size

600x520x230 (mm)

Custom configuration available by aircraft specifications and type

Min 1.8m ~ Max 15m

| Inspection Items | |

|---|---|

Item 1 | Motor RPM |

Item 2 | Motor coilopen/short |

Item 3 | Blade installation direction |

Item 4 | Blade balance |

Item 5 | Arm structural fatigue |

Item 6 | ESC operation frequency |

Item 7 | Drive unit response time |

Item 8 | Drive unit balance |

Item 9 | Aircraft vibration frequency |

Item 10 | Exterior (crack, scratch, structure, etc.) |

Item 11 | Thermal status |

Item 12 | Battery charge status |

Item 13 | Magnetic sensor auto calibration |

Item 14 | FCC electronic status |

Item 15 | Onboard sensors status |

To be customized by customers' needs