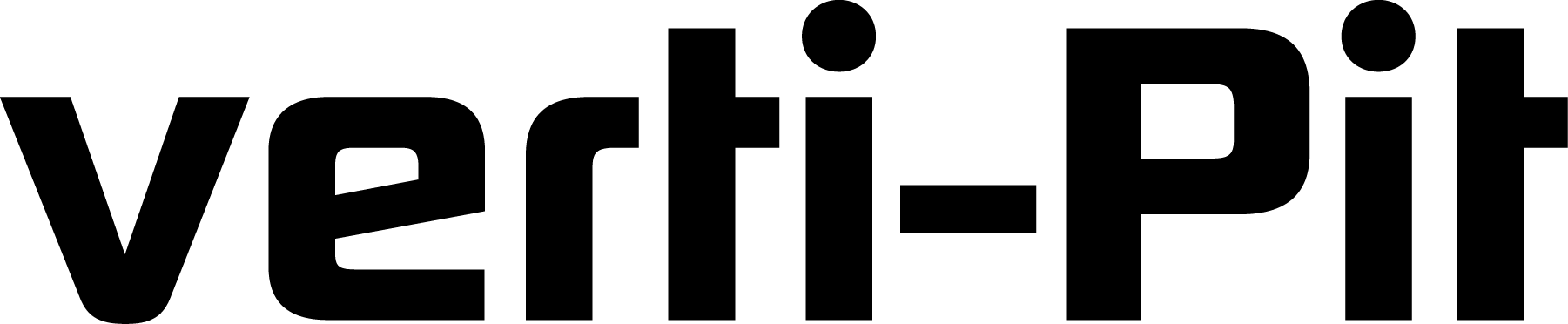

Smart Landing Pad

Ensuring drone safety before takeoff is not an option, but a must.

Non-contact aircraft defect diagnosis

Acquisition of key component data such as motor, blade, control unit, and body within seconds without disassembling or connecting the drone

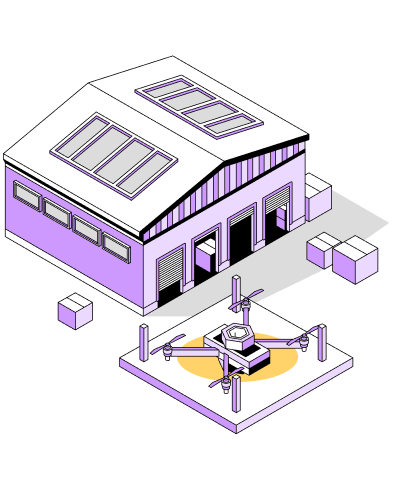

Robust infrastructure integration structure

Integrated and installed at fixed operational bases, ensuring stable performance for repetitive and large-scale inspections

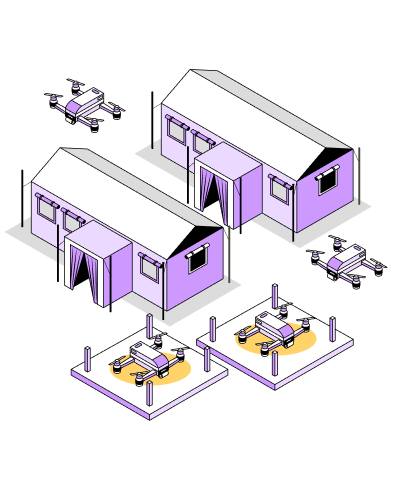

Expandable modular type

System expandable by adding modules according to aircraft size and diagnostic requirements

Customized sensor placement

Adjusting the position of built-in sensors to match the height and width of the aircraft

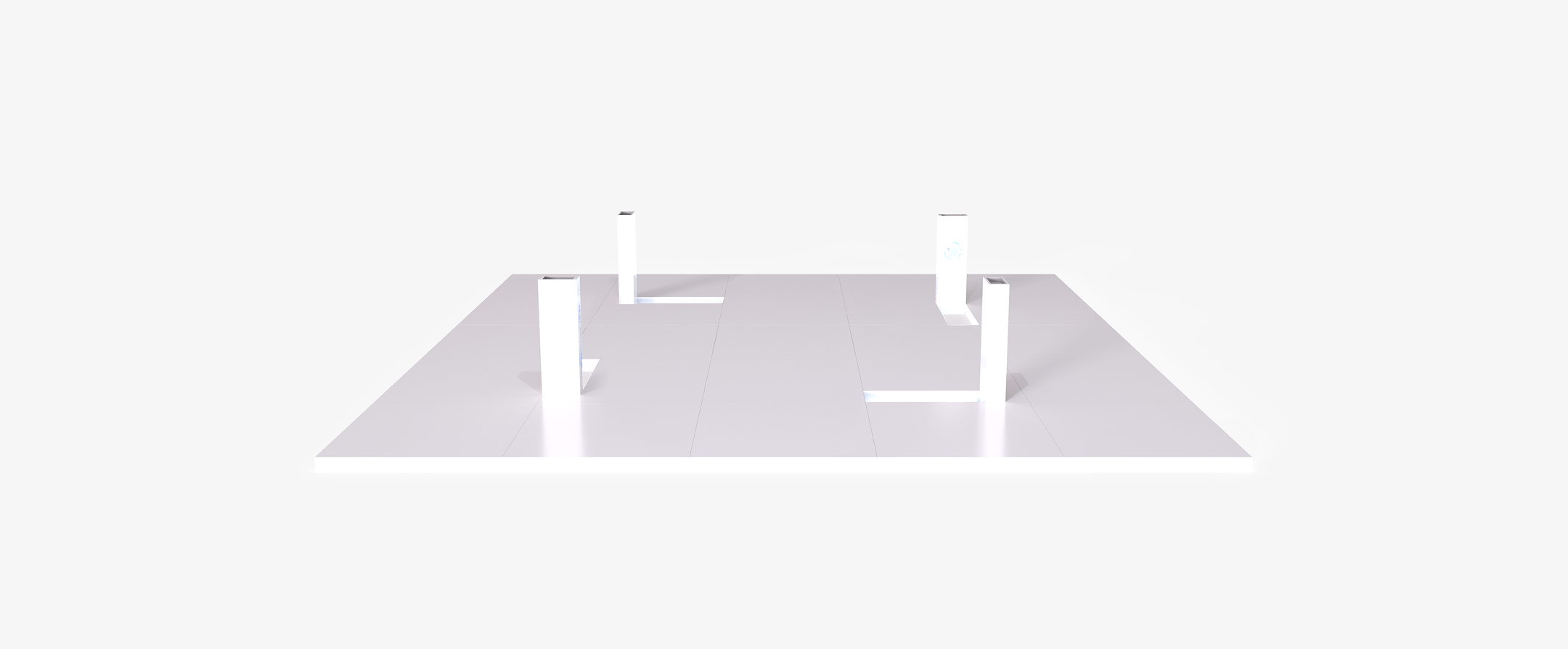

Real-time fault diagnosis

Analysis of inspection data obtained through sensors and fault diagnosis

Aircraft aging diagnosis

Predicting maintenance timing by analyzing part wear and aging based on inspection history

Automatic application of standard inspection items

Automation of inspection lists according to institutional/corporate requirements → Prevention of missed inspections

Providing operational insights

Presenting improvement points for abnormal patterns and operational efficiency based on accumulated data

How to use

Fix drone position

Position the drone accurately on the pad before takeoff and after landing

Automatic data acquisition

Acquire data through onboard sensors during arming status

AI data analysis

Determine abnormalities through fault diagnosis algorithms

Predictive maintenance

Predict maintenance timing through analyzed data

Customer value

Accident prevention through automatic detection of defects before takeoff

- Automatic inspection of 9 items including motor rotation speed, direction, and balancing

- Pre-emptive blocking of potential risks before takeoff → Reduction in accident rate

87.5% reduction in inspection time, improved operational efficiency

- Manual 8 minutes → Automated 1 minute

- Same quality inspection without skilled personnel → Reduced labor burden

Quantified takeoff judgment and automatic recording

- Numerical-based inspection → Provides clear criteria for historical records

- Automatic saving and analysis of inspection results → Enables history management and analysis for each aircraft

Use case

Civilian drone operation sites

Pre-inspection of logistics drones, reconnaissance drones, industrial drones, etc.

Public/Defense operation facilities

Check the aircraft status before mission deployment

Drone educational institutions and certification centers

Automation of takeoff safety verification process

Urban Air Mobility (UAM) based infrastructure

Utilized as an automatic inspection system at takeoff/landing points

SPEC

Size

3000x3000x150 (mm)

Custom configuration available by aircraft specifications and type

Min 1.8m ~ Max 15m

| Inspection Items | |

|---|---|

Item 1 | Motor RPM |

Item 2 | Motor coilopen/short |

Item 3 | Blade installation direction |

Item 4 | Blade balance |

Item 5 | Arm structural fatigue |

Item 6 | ESC operation frequency |

Item 7 | Drive unit response time |

Item 8 | Drive unit balance |

Item 9 | Aircraft vibration frequency |

Item 10 | Exterior (crack, scratch, structure, etc.) |

Item 11 | Thermal status |

Item 12 | Battery charge status |

Item 13 | Magnetic sensor auto calibration |

Item 14 | FCC electronic status |

Item 15 | Onboard sensors status |

To be customized by customers' needs